3 Types of Headlights

Parabolic

The light source hits a parabolic reflector that will determine the main focus of the beam. The parabolic reflector

with its highly reflective "silvered" or chromed surface. First used in the early 1900s, they have been refined

for the last 100 years.

The parabolic reflector is most efficient in applications that don’t require sharp cut-offs (such as low-beam light patterns), but allow all of the reflector and lens size to be utilized. Larger parabolic reflectors project more light, making them ideal for applications that aren’t restricted by available installation space.

Free Form or Free Surface

Similar to Parabolic with a clear front lens. The reflector surface and bulb position are optimized by high-performance

computers to achieve a correspondingly high light output.

Reflector’s surface calculations are point by point to illuminate specific areas of the road. This lighting technology

is clearly identified by the crystal clear cover lens that gives the headlamp its unmistakable character.

Developed by Hella and used for the first time in series production in 1988, this technique made it possible to achieve

excellent beam pattern solely produced by the shape of the reflector - the cover lens with a purely protective function. "Reflector" is

a term commonly used to describe both Parabolic and Free Form lighting.

Projector/Ellipsoid

The principle is similar to that used in a slide projector. An parabolic lens (reflector) directs the light to

a focusing lens (projector) that aims and projects it. A shield positioned between the reflector and projector provides

the desired DOT, ECE, JDM cutoff.

Bulb Types

HALOGEN

Halogen Lightning (Halogen) has been used in automotive lighting for 50+ years. Halogen is a conventional direct-current

direct-circuit setup. The bulb houses a filament commonly made of tungsten metal - a delicate loose coil of exotic

wire. The filament is held up by two chemically-treated, copper-coated steel (or molybdenum) lead wires. On some bulbs,

like the 9006/HB4 shown below, the capsule encases the wire and iss capped at the end with nickel-plated brass film.

The bulb itself is also filled with a noble gas of some sort.

When electrical current is supplied to the positive lead terminal in the halogen bulb, it crosses a path of tungsten

wire, which has very high electrical resistance. This high resistance produces the heat and light as a byproduct. Halogen

low beams will normally operate on 55 watts of power. Different bulb types operate at different power ratings and outputs

with varying efficiency.

Halogen bulbs produce more heat than light (incandescence), which is an inefficient usage of potential energy. During

usage, the tungsten atoms begin to evaporate from the filament due to the extreme heat (hence why more tightly packed

tungsten coils are better for longer life).

As tungsten evaporates, it deposits itself on the cooler surface of the glass bulb (hence the black residue when your

bulb ceases function), and the filament becomes thinner and more brittle (subject to lower thresholds of shock). Eventually

the filament will evaporate enough that the tungsten breaks the electrical circuit. Hence - a dead bulb.

Because tungsten evaporates quickly, bulbs are usually filled with inert gases like argon, krypton, and xenon. These

gases create a level of pressure that tungsten evaporation. Once a tungsten atom leaves the surface of the filament,

it is immediately blocked by giant xenon particles.

Xenon is most common because it is the heaviest of the inert gases. This explains many of the claims of Halogen sales

that they have "xenon-like" properties. Xenon-filled halogen bulbs will not work indefinitely because tungsten

has smaller atoms than xenon, and the atoms will deposit themselves somewhere else eventually. Halogen can also broken

by overpowering the bulb (running 100W through a 50W bulb)

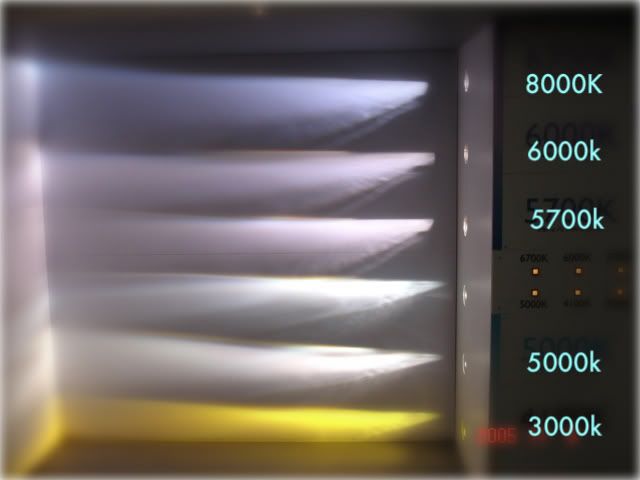

HID - gas discharge - uses a capsule (bulb) with two adjacent and connected electrodes positioned in close proximity to each other. The two electrodes return to the HID ballast, an electronic module that has a circuit board lined with several small high current capacitors, transistors, and resistors. This ballast can act as an ignition box or have a built in external ignition box (ignitor) to fire up the gas discharge process, and acts as a constant power flow control unit. The HID capsule is filled noble gases as well as alkali earth metal salts. Rather than as a buffer (as with halogen), the gases themselves are the lighting source. For quick ignition, the ballast takes in a small amount of input power of 35 watts at 12 volts and inducts a solid-state charge of 25,000 volts to the positive electrode creating a high-powered arc of electricity across the electrodes, which excites noble gases into discharging photon particles (light). This process is known as the Gas Discharge Principle. If the ballast is efficient, then the ignition process and constant flow of power can be self-contained within a single unit . Alternatively, to minimize circuit board complexity and diminish the potential for high startup energy from negatively affecting the lifespan of the constant flow circuits, an external circuit board exclusively used for the ignition process may be used. The light produced is cooler than halogen, uses less power - and is therefore more efficient - and produces more light. HID Capsules can burn at many different temperatures (changing the mixture of the gases) but as the Kelvin Temperature (the way light color is measured) goes up, the resulting output of Lumens goes down.

TERMS

- Watt Electrical power (w)

- Volt Electrical charge (v)

- Kelvin Color temperature (K)

- Lumen Light brightness (lu)

- Candela Light intensity (cd)

- Ampere Electrical current

- Cut-off Line at which light output ceases to project

- Beam Pattern Projected light pattern described by angle of lateral dispersion, width and depth of illumination.

- Capsule HID Bulb aka Gas Discharge Capsules.

- Optics The lighting control assembly structured around the bulb, which effects the dispersion of light and its characteristics to a great degree. See "3 Types of Headlights"

- HID (High Intensity Discharge) = gas Discharge (aka Xenon)

- Halogen = Incandescence (aka Filament)

- PNP plug n play adapters.

Key Statistics

- Up to 3X lower power usage (HID = 35W vs Halogen = 55-100W)

- Up to 4X light output (HID = 2400-3200lu vs Halogen = 800-1700lu)

- Up to 6X longer lasting (HID = 2500hr, halogen = 400hr)

- Up to 10X more intensity (HID = 202,500cd vs Halogen = 21,000cd)

Main Benefits of HID Lighting

- It is less fatiguing to the driver and other motorists (producing less infrared and ultraviolet light)

- Road illumination, color contrast, and accuracy of color temperature on the road is improved.

- Requires no coloring of the glass (like Halogen) to produce color contrast (which decreases Halogen life span)

- With a quality housing unit, HID produce a wider and deeper beam pattern

- It maintains effectiveness throughout the full lifespan of the bulbs.

- Evenly distributed light without hotspots or degraded fringe output.